Call Us

07971459101

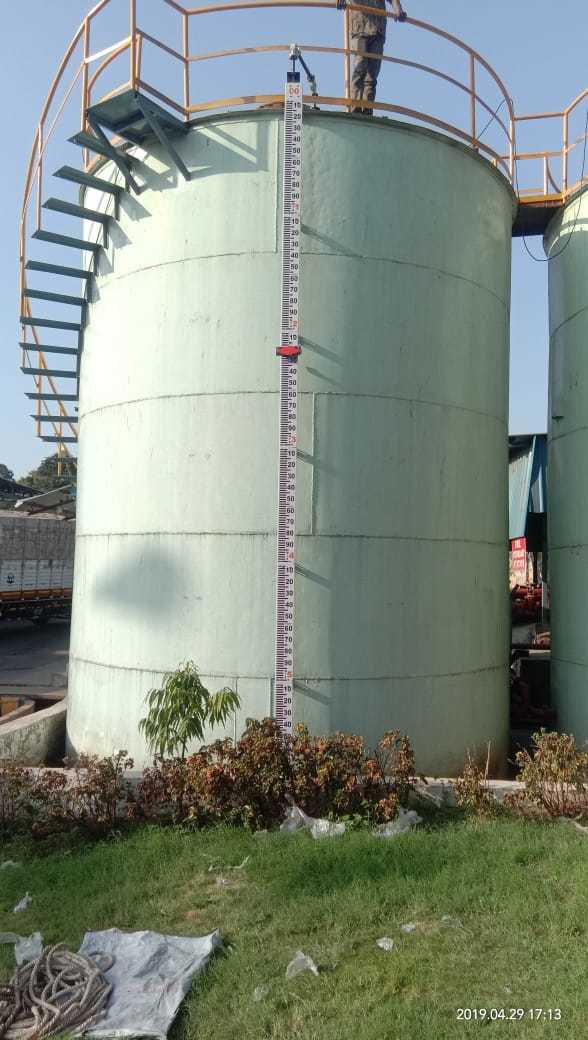

Tank Level Indicator

6660 INR

Product Details:

- Frequency 50 Hertz (HZ)

- Protection Level IP65

- Application Industries

- Accuracy 2 %

- Warranty 1 Year

- Click to view more

X

Tank Level Indicator Price And Quantity

- 1 Set

- 6660 INR

Tank Level Indicator Product Specifications

- 1 Year

- 50 Hertz (HZ)

- 2 %

- Industries

- IP65

Tank Level Indicator Trade Information

- All India

Product Description

The float is attached to a Tank Level Indicator, which passes through 2 nos. friction less specially designed pulleys.The Pulleys in turn are connected to a pointer, which moves on a graduated scale by the side of the tank.Features of Tank Level Indicator: 1. Clear visibility2. Powder coated screen printed scale board3. Less corrosion powder coated finish4. Easy movement nylon roller pointer glides effortlessly5. No guide wire specially designed self centering float/Anchor plate optional6. Non- stretching multi strand wire rope in SS/PP7. Dust free housing for pulleys - minimizing friction in movement8. Easy to install, modular design9. Vapour tight-version for evaporating fluids Product details Country of Origin Made in India DIN Size 96 x 96 mm Type Mechanical Accuracy 2% Brand Kabir Current 1 A Usage/Application Industrial Application of Tank Level Indicator: 1. Industrial Tanks: Monitoring and controlling the levels of liquids such as chemicals, oils, and fuels in industrial storage tanks to prevent overflows and ensure a constant and reliable supply.2. Water Treatment Plants: Managing the levels of water in treatment tanks, ensuring a consistent flow for purification processes, and preventing contamination or shortages.3. Agriculture: Monitoring liquid levels in agricultural tanks for fertilizers, pesticides, and water, optimizing resource usage, and preventing over-application or shortages.4. Oil and Gas Industry: Tracking the levels of crude oil, refined products, and various chemicals in storage tanks to prevent spills, optimize inventory management, and ensure safe and efficient operations.5. Chemical Processing Plants: Controlling levels in chemical storage tanks to prevent spills, maintain process efficiency, and ensure the safety of workers and the environment.6. Food and Beverage Industry: Monitoring levels in tanks containing ingredients, additives, or finished products to control production processes, avoid waste, and ensure product quality.7. Environmental Monitoring: Monitoring levels of liquid waste or runoff in environmental storage tanks to prevent pollution and comply with regulations.8. Water Wells and Reservoirs: Monitoring water levels in wells and reservoirs for municipal water supply, agricultural irrigation, or groundwater management.9. Tanker Trucks and Trailers: Installing portable tank level indicators for monitoring liquid levels during transportation to ensure safe and efficient delivery without spills.10. HVAC Systems: Controlling water levels in HVAC system tanks to maintain optimal performance, prevent equipment damage, and ensure efficient heating or cooling.11. Fire Protection Systems: Monitoring water levels in fire protection tanks to ensure an adequate water supply for firefighting operations.12. Wastewater Treatment Plants: Managing levels in wastewater treatment tanks to optimize the treatment process, prevent overflows, and comply with environmental regulations.13. Power Plants: Monitoring coolant levels in power plant tanks to ensure proper equipment cooling and prevent damage to turbines and other machinery.14. Automotive Industry: Controlling fluid levels in manufacturing processes for vehicles, ensuring a consistent supply of fluids for lubrication, cooling, and other applications.15. Mining Operations: Monitoring levels in tanks containing chemicals, water, or processing solutions in mining operations to ensure the efficiency of mineral processing and prevent environmental impact.Tank Level Indicator FAQ: Q. What is a tank level indicator?Ans: A tank level indicator is a device or system designed to measure and display the level of liquid inside a tank. It provides valuable information about the quantity of the substance stored in the tank.Q. Why are tank level indicators important?Ans: Tank level indicators are crucial for monitoring and managing fluid levels in various industries such as manufacturing, agriculture, oil and gas, and water treatment. They help prevent overflows, shortages, and ensure efficient resource management.Q. How do tank level indicators work?Ans: Tank level indicators use different technologies, including ultrasonic, float sensors, radar, or pressure sensors. These sensors detect the level of the liquid and transmit the data to a display unit or control system.Q. What types of tank level indicators are available?Ans: Common types include ultrasonic level indicators, float level indicators, radar level indicators, capacitance level indicators, and differential pressure level indicators. The choice depends on the specific application and the characteristics of the stored fluid.Q. Can tank level indicators be used for different types of liquids?Ans: Yes, many tank level indicators are designed to work with various liquids, including water, chemicals, oil, and more. However, its essential to choose an indicator compatible with the specific properties of the stored liquid.Q. Are tank level indicators suitable for outdoor use?Ans: Yes, many tank level indicators are designed to be weatherproof and can withstand outdoor conditions. However, its crucial to check the specifications and choose a model suitable for the environmental conditions in which it will be installed.Q. How accurate are tank level indicators?Ans: The accuracy of tank level indicators can vary depending on the technology used and the specific model. High-quality indicators can provide precise measurements, but regular calibration and maintenance are essential to ensure accuracy.Q. Can tank level indicators be integrated with other systems?Ans: Yes, many tank level indicators come with integration capabilities, allowing them to be connected to control systems, alarms, or data logging devices. This integration enhances the overall monitoring and management capabilities.Q. What maintenance is required for tank level indicators?Ans: Regular maintenance, including cleaning, calibration checks, and inspection of sensor components, is essential to ensure the continued accuracy and reliability of tank level indicators.Q. Can tank level indicators be retrofitted to existing tanks?Ans: In many cases, tank level indicators can be retrofitted to existing tanks. However, its crucial to consider the tanks design and the compatibility of the indicator with the specific requirements of the installation.FAQs of Tank Level Indicator:

Q: What is the protection level of the Tank Level Indicator?

A: The Tank Level Indicator has a protection level of IP65.Q: What industries or applications is this Tank Level Indicator suitable for?

A: The Tank Level Indicator is designed for industrial applications.Q: What is the frequency specification of the Tank Level Indicator?

A: The frequency specification of the Tank Level Indicator is 50 Hertz (HZ).Q: What warranty is provided with the Tank Level Indicator?

A: The Tank Level Indicator comes with a 1-year warranty.Q: What is the accuracy of the Tank Level Indicator?

A: The Tank Level Indicator has an accuracy of 2%.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Level Indicator' category

"We are expecting inquiries from international market"

And also we want more inquires from countries like Middle East Countries, African Countries, South East Asia and North America.

And also we want more inquires from countries like Middle East Countries, African Countries, South East Asia and North America.