Call Us

07971459101

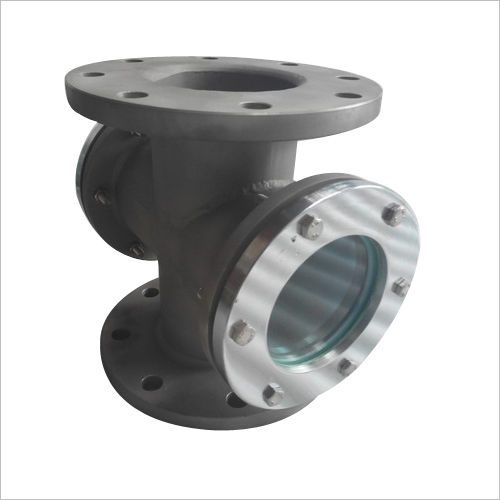

Sight Glass Indicator

Product Details:

- Structure Solid

- Usage Industrial

- Material SS

- Size Standard

- Color Silver

- Surface Polished

- Click to view more

X

Sight Glass Indicator Price And Quantity

- 1 , , Unit

Sight Glass Indicator Product Specifications

- Silver

- Standard

- SS

- Solid

- Polished

- Industrial

Sight Glass Indicator Trade Information

- 15-20 , , Unit Per Day

- 1 Week

Product Description

Sight glass indicator is a viewing glass, which lets the users to see the levels of liquids & gases that go through a critical point of your design. This indicator is extremely useful in examining the changes made in pressure. In addition, it is useful for monitoring the quality of lubricant as well as oil. This indication solution serves the best in every scenario. This is suited for advanced monitoring applications. It is available with sight glass designs, ease of sealing, less maintenance, and accessibility in good pressure/temperature combinations in ample sizes.Sight Glass Indicator Applications: 1. Chemical Processing Industry: Chemical Reactors: Sight glasses are used to monitor reactions inside chemical reactors, ensuring proper mixing and reaction progress. Storage Tanks: Sight glasses help operators observe the levels and conditions of chemicals stored in tanks. 2. Food and Beverage Industry: Brewing and Distillation: Sight glasses are employed in the production of beverages to monitor fermentation, liquid levels, and clarity. Food Processing: Used to observe the flow and consistency of various food products during processing. 3. Pharmaceutical Industry: Reaction Vessels: Sight glasses are crucial for monitoring reactions in pharmaceutical manufacturing to ensure quality and consistency. Mixing Tanks: Used to observe and control the mixing of pharmaceutical ingredients. 4. Oil and Gas Industry: Pipeline Monitoring: Sight glasses enable operators to visually inspect the flow of oil or gas in pipelines. Pressure Vessels: Sight glasses are employed in vessels to monitor pressure levels and the state of the fluids. 5. HVAC Systems: Cooling Systems: Sight glasses are used to monitor the refrigerant levels and conditions in air conditioning and refrigeration systems. 6. Water Treatment Plants: Water Filtration Systems: Sight glasses help monitor the clarity and flow of water in filtration processes. Chemical Dosing: Used to observe and control the addition of chemicals for water treatment. 7. Automotive Industry: Hydraulic Systems: Sight glasses in hydraulic systems allow operators to monitor fluid levels and check for contamination. 8. Power Plants: Boiler Systems: Sight glasses help monitor water levels and conditions in boiler systems. Cooling Towers: Used to observe the water flow and conditions in cooling tower systems. 9. Laboratory Equipment: Reaction Chambers: Sight glasses are used in laboratories to observe reactions and experimental processes. Distillation Apparatus: Used to monitor the distillation process. 10. General Industrial Processes: Pipelines and Conduits: Sight glasses are employed in various industrial processes to visually inspect the flow of fluids. Pressure Gauges: Some pressure gauges incorporate sight glasses to allow direct visual inspection of pressure levels. Sight Glass Indicator FAQ: Q. What is a sight glass indicator?Ans: A sight glass indicator is a transparent or translucent window installed in a vessel, pipeline, or system to allow visual inspection of the contents or processes inside.Q. What are the main components of a sight glass indicator?Ans: The main components typically include a transparent or translucent material (glass or plastic), gaskets or seals to maintain integrity, and mounting hardware.Q. What are the common materials used for sight glass windows?Ans: Sight glass windows are often made from materials such as tempered glass, borosilicate glass, acrylic, or polycarbonate, depending on the application and the compatibility with the substances being observed.Q. What is the purpose of a sight glass indicator?Ans: The primary purpose is to provide a visual means for operators to monitor levels, flow, color, and conditions of liquids or gases within a system, ensuring proper functioning and safety.Q. Where are sight glass indicators used?Ans: Sight glass indicators find applications in various industries, including chemical processing, food and beverage, pharmaceuticals, oil and gas, HVAC systems, water treatment plants, automotive, power plants, and general industrial processes.Q. How do sight glass indicators work?Ans: Sight glass indicators allow light to pass through, enabling operators to visually inspect the internal processes or contents of a system. They are sealed to prevent leakage and are often equipped with additional features like lighting or markings for enhanced visibility.Q. Are there different types of sight glass indicators?Ans: Yes, there are different types, including flat sight glasses, tubular sight glasses, and sight glass windows with special features like lighting, wipers, or coatings for specific applications.Q. What factors should be considered when selecting a sight glass indicator?Ans: Factors to consider include the material compatibility with the substance being observed, pressure and temperature ratings, size, visibility requirements, and environmental conditions.Q. How is maintenance performed on sight glass indicators?Ans: Maintenance may involve periodic cleaning of the sight glass, checking seals for wear, and replacing any damaged components. Proper care helps maintain visibility and ensures the indicators effectiveness.Q. Can sight glass indicators be used in hazardous environments?Ans: Yes, there are sight glass indicators designed for use in hazardous environments. They may be constructed with materials and features that meet specific safety standards and regulations.Q. Can sight glass indicators be customized for specific applications?Ans: Yes, manufacturers often provide customization options based on the unique requirements of different industries and applications.Q. Are there specific safety precautions for using sight glass indicators?Ans: Operators should follow safety guidelines, including wearing appropriate protective gear, ensuring the sight glass is rated for the application conditions, and avoiding direct contact with hot or hazardous substances.cFAQs of Sight Glass Indicator:

Q: What is the structure of the Sight Glass Indicator?

A: The structure of the Sight Glass Indicator is solid.Q: What is the main usage of this product?

A: The Sight Glass Indicator is designed for industrial use.Q: What material is used for manufacturing the Sight Glass Indicator?

A: The Sight Glass Indicator is made from stainless steel (SS).Q: What is the surface finish of the Sight Glass Indicator?

A: The surface of the Sight Glass Indicator is polished.Q: What is the color of the Sight Glass Indicator?

A: The Sight Glass Indicator comes in a silver color.Q: What size does the Sight Glass Indicator come in?

A: The product is available in a standard size.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Sight Glass (Sight Flow Indicator)' category

"We are expecting inquiries from international market"

And also we want more inquires from countries like Middle East Countries, African Countries, South East Asia and North America.

And also we want more inquires from countries like Middle East Countries, African Countries, South East Asia and North America.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese