Call Us

07971459101

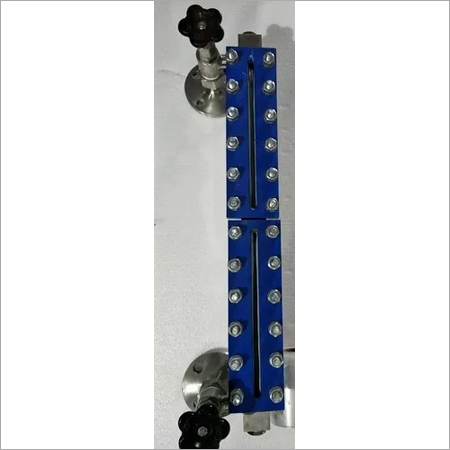

Transparent Level Indicator

10800 INR/Piece

Product Details:

- Protection Level Other

- Sensor Type Mechanical/Visual

- Switch Type Optional Magnetic Float Switch Attachment

- Features Direct Liquid Level Observation, Leakproof, High Pressure & Temperature Compatibility

- Installation Type Flange Mounted / Side Mounted

- Output Visual Level Indication

- Usage & Applications Chemical Industry, Oil & Gas, Water Treatment, Process Plants

- Click to view more

X

Transparent Level Indicator Price And Quantity

- 1 Piece

- 10800 INR/Piece

Transparent Level Indicator Product Specifications

- IP65 (for valves and connections)

- Side or Top Mounted

- Transparent Glass Tube

- Mechanical

- 4 Celsius (oC)

- Measuring Instruments

- 2 mm mm

- Flange Mounted / Side Mounted

- Direct Liquid Level Observation, Leakproof, High Pressure & Temperature Compatibility

- Visual Level Indication

- Chemical Industry, Oil & Gas, Water Treatment, Process Plants

- -20 to 120 Celsius (oC)

- -20 to 120 Celsius (oC)

- None (Mechanical Indication)

- Optional Magnetic Float Switch Attachment

- Depends on size (typically 2-8 Kilograms (kg)

- Mechanical/Visual

- Other

- Gauge/Atmospheric

- Liquid Level Measurement in Tanks and Vessels

Transparent Level Indicator Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque, Telegraphic Transfer (T/T)

- 10000 Piece Per Month

- 1 Days

- Wooden box, Termocoal box, bubble raping

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- ISO

Product Description

A Transparent Level Indicator is a device utilized to visually monitor the level of liquids in tanks or vessels. It is available in two types: Reflex and Transparent. Reflex types offer partial visibility with distinct contrast between liquid and gas phases, while Transparent types provide full visibility. Typically comes in sizes like 1", they have a measuring range of 0-3000 mm. Their features comprise easy installation, sturdy construction, and compatibility with varied fluids. Advantages encompass minimal maintenance, reliable level indication, and suitability for hazardous environments. Widely utilized in industries like water treatment, petrochemicals, and pharmaceuticals for accurate liquid level monitoring and control.

Transparent Level Indicator Specifications:

1. Type: Reflex / Transparent

2. Visibility: Full Visibility / Partial Visibility

3. Size: 1"

4. Measuring Range: 0-3000 mm

5. Model: Tlg

6. Brand: Kabir

High Performance Liquid Level Measurement

Our Transparent Level Indicator is engineered to deliver accurate and reliable liquid level readings in harsh industrial environments. Utilizing a borosilicate glass tube with SS304/SS316 end fittings, it withstands pressures up to 20 bar and temperatures from -20C to 120C. The graduated scale and transparent design allow operators to monitor tank levels visually and precisely.

Versatility in Application and Construction

Designed for use with both corrosive and non-corrosive fluids, this indicator features customizable connections (flanged, screwed, socket welded) and can be supplied with various gaskets (EPDM, Viton, PTFE) to ensure chemical compatibility. Protection options like metal casing or guards further enhance safety, while tool-free maintenance simplifies inspection and cleaning.

Dependable and Safe Operation

This level indicator offers a leakproof build, IP65-rated connections, and is constructed from corrosion-resistant materials for long operational life. It can be flange or side-mounted, fitting a wide range of tank dimensions and nozzle diameters (commonly DN20-DN50). Optional magnetic float switches provide extended monitoring capabilities, supporting a safer, more efficient process.

FAQs of Transparent Level Indicator:

Q: How is the Transparent Level Indicator installed on tanks or vessels?

A: Installation is straightforward; the indicator can be flange-mounted, side-mounted, or top-mounted, depending on tank design. End connections are customizable (flanged, screwed, or socket welded) as per customer requirements, ensuring compatibility with various industrial setups.Q: What types of liquids is this level indicator suitable for?

A: This device is suitable for both corrosive and non-corrosive liquids, thanks to its borosilicate glass tube and SS304/SS316 end fittings. Gasket options like EPDM, Viton, or PTFE offer further chemical compatibility, making it ideal for chemical, oil & gas, water treatment, and process industries.Q: When should the glass tube be cleaned or inspected?

A: Regular inspection and cleaning are recommended, especially when the process fluid is prone to leaving residues. The indicator features a tool-free maintenance design, enabling quick and easy cleaning or inspection of the glass tube to ensure optimal visibility and accuracy.Q: Where can this level indicator be used?

A: It is widely used across various industries such as chemical processing, oil & gas, water treatment, and general process plants. Its robust construction and adaptability make it suitable for tanks and vessels where precise liquid level measurement is vital.Q: What are the benefits of using a transparent level indicator with graduated scale?

A: The transparent glass tube and graduated scale allow for direct visual observation of liquid levels, enhancing monitoring accuracy and process control. The design ensures full visibility between process connections, immediate detection of level changes, and user confidence during operation.Q: How does the integrated drain/vent valve function, and is it mandatory?

A: The integrated drain or vent valve is available upon request, providing convenient draining or venting during maintenance or cleaning. It is optional and can be included based on specific user requirements to further ease operation and maintenance.Q: What makes this indicator particularly suitable for high-pressure and high-temperature applications?

A: Constructed with borosilicate glass and SS304/SS316 end fittings, the indicator withstands pressures up to 20 bar and temperatures from -20C to 120C. Its leakproof and corrosion-resistant materials ensure safe and reliable operation even in demanding environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Level Indicator' category

"We are expecting inquiries from international market"

And also we want more inquires from countries like Middle East Countries, African Countries, South East Asia and North America.

And also we want more inquires from countries like Middle East Countries, African Countries, South East Asia and North America.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese